Reducel

GRI REDUCEL (Reducel SL) is a Spanish family-owned company founded in 1955 by the Zamorano family and, since 2023, has been part of GRI Renewable Industries—an integration that brings together the industrial traditions of the Riberas and Zamorano families. Headquartered in Zaragoza, GRI REDUCEL specializes in manufacturing large-scale components that require extremely high quality standards and highly specific technological processes.

Reducel

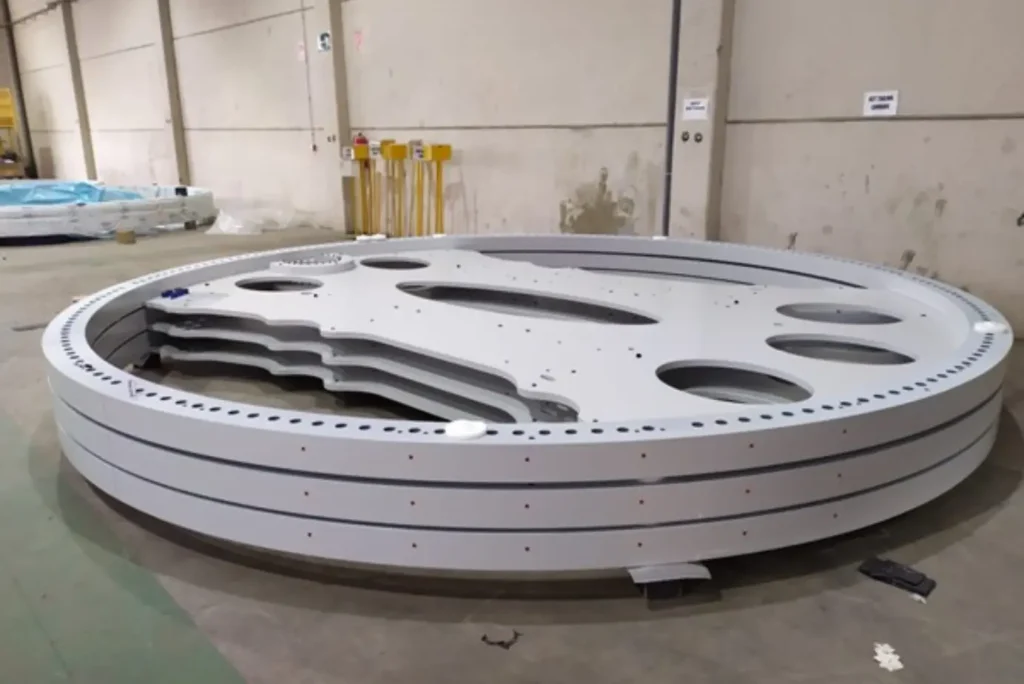

Yaw Rings

Yaw Rings are one of the most critical components in a wind turbine. Their function is to allow continuous orientation of the nacelle relative to the wind direction, ensuring that the rotor always operates under optimal performance and safety conditions. This operation requires extreme precision, high resistance to dynamic loads, and durability capable of withstanding millions of cycles throughout the turbine’s lifespan.

At GRI REDUCEL, we have extensive experience in the design and manufacturing of Yaw Rings, applying highly specialized processes and high-capacity CNC equipment. Thanks to our industrial infrastructure and the knowledge accumulated over more than three decades in the wind sector, we are capable of manufacturing Yaw Rings up to 9,500 mm in diameter, meeting the most demanding standards of quality and traceability.

Our approach combines advanced technology, rigorous dimensional control, and operational flexibility that allows us to adapt to the specific requirements of each client and each wind turbine model. For this reason, GRI REDUCEL has become a trusted partner for the world’s leading turbine manufacturers.

Pitch Plates

Pitch Plates are fundamental elements in the connection between the blade and the hub of the wind turbine. These are stiffening plates installed over the pitch bearings to ensure proper load distribution and provide structural rigidity to the blade–hub assembly. Their function is essential to guarantee the mechanical integrity of the blade, the stability of pitch movement, and the overall reliability of the system even under extreme load conditions.

These components must meet very strict tolerances, exhibit perfect flatness, and ensure optimal mechanical strength, as they operate in an environment subject to fatigue, vibrations, thermal variations, and enormous aerodynamic forces.

At GRI REDUCEL, we have the technological capacity and technical expertise required to manufacture Pitch Plates up to 10,000 mm in diameter and high complexity, using advanced CNC machining processes, high-precision dimensional controls, and complete material traceability. Our approach allows us to meet the specific requirements of each turbine model, ensuring stability, safety, and durability at one of the most sensitive points of the wind turbine.

Bearing Covers

Large machined parts

At our plants in Zaragoza and Basauri, we have the industrial resources necessary to undertake large-scale machining with high technical and logistical requirements. We have specialized equipment and handling capacity to work with components of exceptional dimensions and weight.

We carry out complete machining operations, turning, milling, heat treatments, and surface treatments on parts up to:

- 22,000 mm in length.

- 6,000 mm in height.

- 100 tons in weight.

- Turning of components up to 10,000 mm in diameter.

- Gear cutting up to 9,500 mm.

General machining

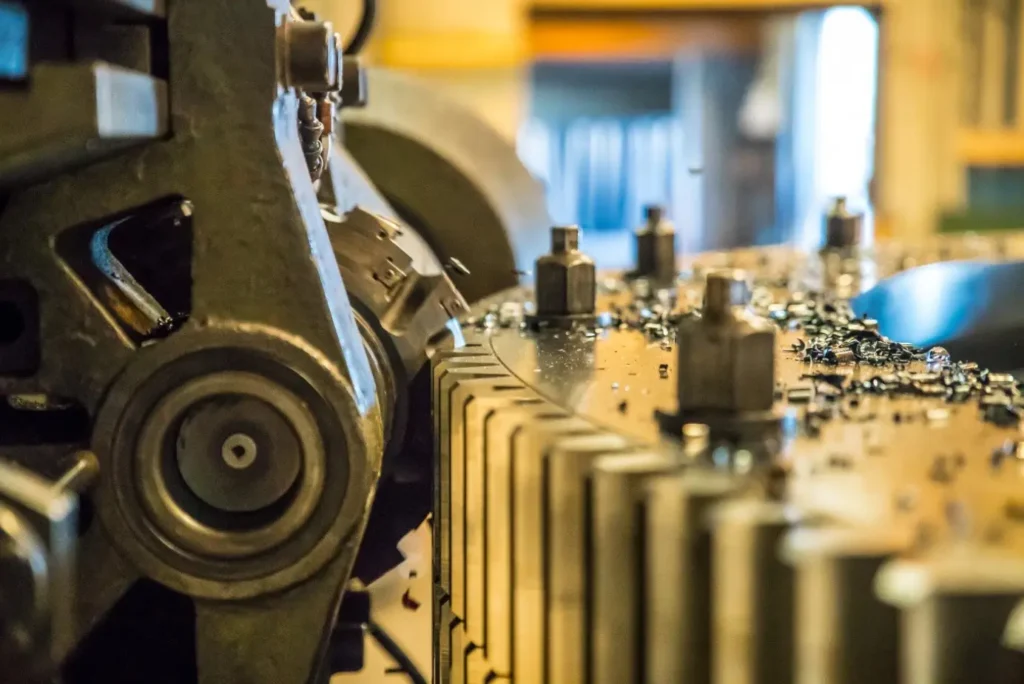

Machining has been part of GRI REDUCEL’s DNA since its origins in 1955, when the company—then under the ANZA brand—specialized in the manufacturing of high-precision gears and reducers. That initial experience, based on technical mastery, dimensional accuracy, and craftsmanship, has evolved into one of our main industrial pillars.

Today, more than six decades later, we maintain that founding spirit, combining accumulated knowledge with state-of-the-art CNC machinery and highly specialized production processes. This trajectory allows us to tackle everything from highly complex machining to large-volume components, always with the same commitment: precision, reliability, and technical excellence.