This project has been co-financed by CDTI and the European Regional Development Fund (ERDF), being Windfit

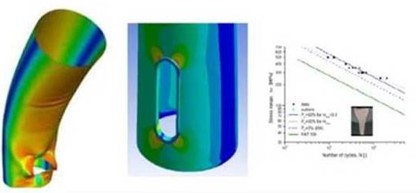

The wind sector seeks to increase energy efficiency per wind turbine, which translates into taller towers and higher power turbines. This process means that the wind shafts or towers increase their thickness, diameter, and weight, which implies higher manufacturing costs. To address this need, GRI Renewable Industries is developing the WINDFIT project, a new generation of more efficient and lighter wind turbines based on advanced models of optimized structural calculation.

The objective of this project is to develop a new concept of wind shafts, from the initial stage of product design, from new calculation models, optimizing their unique elements and welded joints, to the development of specific manufacturing processes that minimize distortions and stresses generated in the shaft.

The total amount of the aid is €967,113.30 (eligible project budget €1,528,308.00).

With WINDFIT, the aim has been to achieve a significant reduction in thickness, as well as a decrease in the average section diameter concerning the current standard shaft. This new generation of designs will respond to future large wind turbines that are expected to reach, competitively, 10MW in the coming years. The project is completed, and the results obtained are those proposed both in efficiency of the wind farms, weight reduction, as well as the obtaining of a tool for the development of complex products of high structural quality.

We must highlight the fact that this project has been classified as a Research and Development project by the Center for the Development of Industrial Technology (CDTI), which means obtaining very significant funding to promote the project.