Technical excellence in structural design

GRI R&D Engineering is a specialized business unit of GRI Renewable Industries, exclusively dedicated to the development of wind turbine towers.

Its goal is to lead innovation and technical excellence in structural design, collaborating with the main manufacturers in the wind energy sector.

Product Design

GRI R&D Engineering develops advanced solutions for wind turbine towers, combining innovation, efficiency, and sustainability. Its team has designed hybrid and tubular towers optimized in weight, cost, and performance, tailored to the specific needs of each customer by incorporating the latest solutions developed in its own R&D&I centers. It offers a comprehensive service that covers everything from conceptual design to certification, manufacturing, and installation.

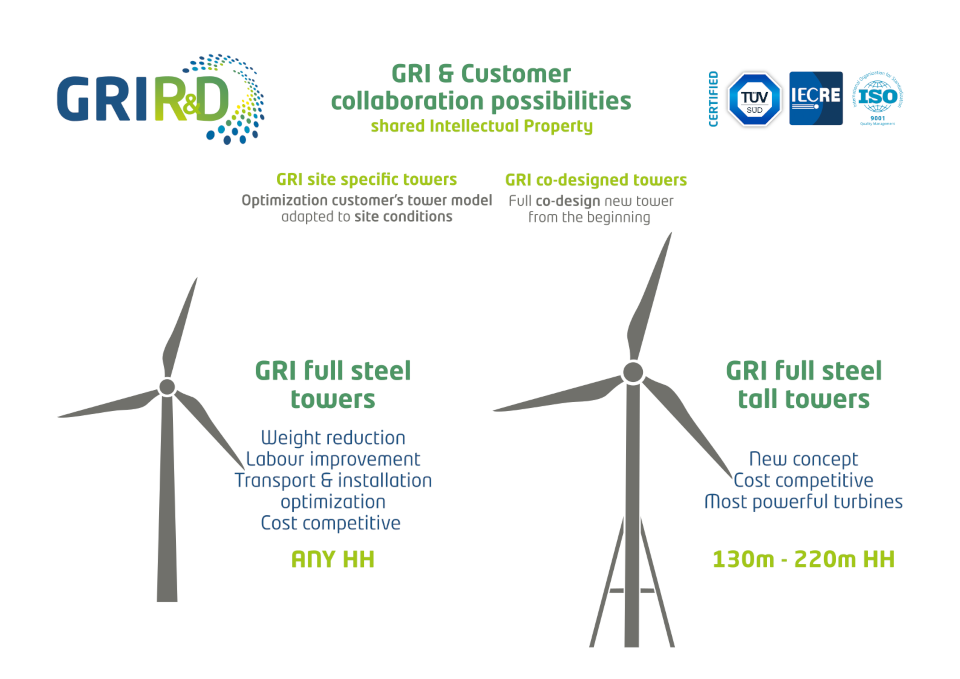

Design Possibilities

GRI R&D Engineering works closely with its clients in the design of wind turbine towers through various cooperation models. From optimizing existing towers for specific site conditions to the complete co-design of new towers from the start of the project.

It offers specialized solutions tailored to markets with cost or industrial capacity limitations All developed designs are certified by external entities, ensuring compliance with the highest technical standards.

In addition, the entire design process, from structural definition to final documentation, is carried out under a quality management system certified according to ISO 9001.

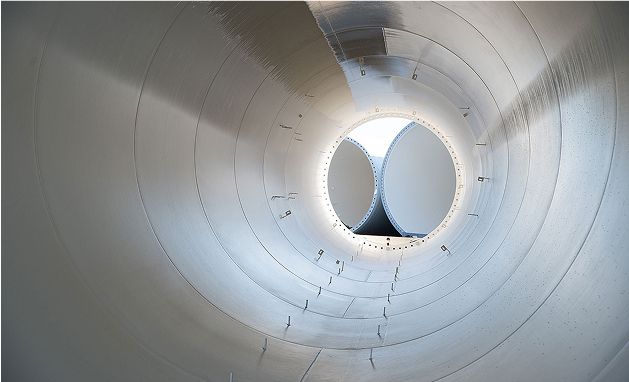

High-rise tower design

GRI R&D Engineering has developed a full-steel tubular tower with three satellites, an innovative solution for high-power wind turbines with hub heights ranging from 140 to 220 meters.

This design improves energy efficiency, reduces land use, and provides greater structural stability. Its ease of transport, scalability, and cost competitiveness make it an ideal option for turbines above 4.5 MW, especially at sites with high load requirements.

Additionally, it maximizes energy capture and minimizes the environmental impact of the project.

Our Commitment

GRI Renewable Industries’ commitment to innovation is reflected in a business unit dedicated to R&D&I. GRI R&D Engineering drives new concepts, materials, design and manufacturing processes, optimizing the product life cycle and reducing costs through vertical integration across the entire value chain.

R&D Centers

Headquarters Madrid

Seville

Turkey

Featured Projects

CDTI Innovación

GRI R&D: Research of structural solutions and innovative methodologies to improve wind towers.

CDTI Innovación and FEDER

GRI R&D: New advanced solutions for internal structural elements for wind turbine superstructures.

Perte Naval

GRI: Research of new design solutions and manufacturing of superstructures for floating offshore wind power.

CDTI Innovación

GRI R&D: Development of new critical structural elements for third generation wind towers.

CDTI and FEDER

GRI R&D: New generation of more efficient and lighter wind shafts based on advanced models of optimized structural calculation.

CDTI and FEDER

GRI Sevilla: Disruptive Intelligent Machine Vision Solutions for Offshore Wind Power Components.

IDEA

GRI Sevilla: Industrial research on a new generation of offshore wind energy metallic substructures.

CDTI Innovación

GRI Sevilla: Development of self-balancing collaborative robot based on neuro fuzzy models with nonlinear control laws.

CDTI

GRI R&D : Disruptive structural design with bonded satellite bodies, optimizing traction and compression, and reducing dimensions without affecting height.

CDTI

GRI: Develop a new concept of onshore concrete tower solution for the support of state-of-the-art wind turbines.

CDTI

GRI: To develop new versatile structural solutions, capable of being integrated into the structural elements of an existing wind turbine.

At the forefront of technology

GRI R&D Engineering develops advanced solutions for wind turbine towers, combining innovation, efficiency, and sustainability. Its team has designed hybrid and tubular towers optimized in weight, cost, and performance, tailored to the specific needs of each customer by incorporating the latest solutions developed in its own R&D&I centers. It offers a comprehensive service that covers everything from conceptual design to certification, manufacturing, and installation.

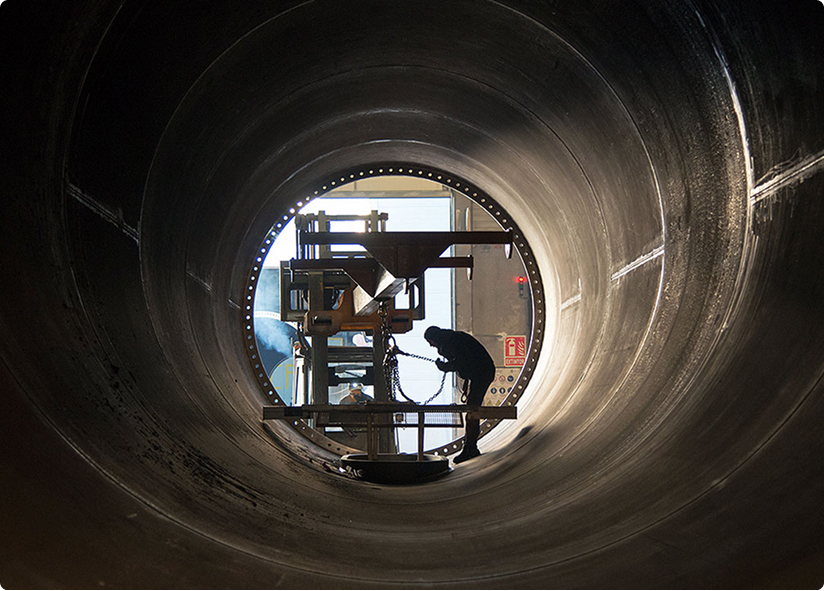

New types of welding

The transition to larger wind towers with better structural design has driven the evolution of manufacturing processes, especially in the field of welding. New technologies are optimising costs, production times and structural quality. From the R&D Department at GRI, we are exploring the application of robotic systems and new welding technologies in the wind tower manufacturing sector.

Artificial vision systems are being tested and trialed to enable automation in both longitudinal and circular welding, achieving increased repeatability and weld quality, reduced cycle time, and improved traceability and quality control of the process.

At the same time, there is a hybrid welding cell HLAW (Hybrid Laser Arc Welding) designed for large thicknesses—a new welding technology whose potential application to the sector would offer advantages in precision and speed in the process that are unattainable with current technologies.

Additive technologies

Our R&D team has developed and tested metallic tower internals manufactured using 3D printing with stainless steel filament.

This technology enables the creation of complex geometries and optimized thread designs, improving mechanical performance in wind turbine components. Through sintering processes and pull-out resistance tests, the structural integrity and durability of the printed parts have been validated.

Additive manufacturing with steel enhances design flexibility, reduces machining costs, and shortens production lead times, paving the way for next-generation industrial applications.

Selfbalance

CDTI Innovación has agreed to provide funding to GRI Towers Sevilla S.L. for the development of the R&D Project “Development of a self-balancing collaborative robot based on neuro-fuzzy models with nonlinear control laws (SELFBALANCE).”

The main objective of the project is the development of an industrial welding collaborative robot with self-balancing intelligence, based on neuro-fuzzy control models with nonlinear control laws, allowing adaptation to process-related disturbances and providing a new manufacturing route for wind superstructures such as offshore towers or monopiles.

This new robot will set a benchmark in the development of new manufacturing routes for circular welding of large conical pieces such as towers and monopiles in the offshore wind sector, enabling the assembly of the entire section prior to the welding process, which will be carried out continuously, as well as allowing changes in the sequencing of internal and external welding for the application of new disruptive bevels for the industry.

This project is co-financed by CDTI Innovación.

AI applied to the production process

Artificial intelligence (AI) is transforming the wind tower production process, especially in areas such as design, manufacturing, predictive maintenance and operational optimisation. GRI is at the forefront in this field, with several innovation projects where we are applying AI to optimize key processes in wind tower manufacturing, including inspection, welding, predictive maintenance, and quality control.

The results obtained so far are promising, and some are already in the industrialization phase, generating process time savings that in some cases exceed 20% gross, that is, without considering the added impact of improvements in directly related processes, which receive a higher-quality intermediate product and therefore create an immediate “continuous improvement” effect.